Develop platforms to plan, schedule, and monitor production workflows, optimizing resource utilization and minimizing downtime for better operational efficiency.

Implement inventory management solutions to track raw materials, components, and finished goods in real-time, reducing stockouts, overstocking, and waste.

Create systems that integrate procurement, supplier management, and logistics, ensuring timely delivery of raw materials and seamless supply chain operations.

Utilize AI and IoT sensors to predict equipment failures before they occur. This helps reduce unplanned downtime, increase equipment lifespan, and improve production efficiency.

Develop systems to automate quality control processes, including real-time defect detection and compliance tracking, ensuring consistent product quality.

Build MES platforms to monitor and control shop floor activities, providing real-time visibility into production performance, process compliance, and output efficiency.

Streamline production workflows with automation, scheduling optimization, and real-time monitoring, improving throughput and reducing downtime.

Real-time inventory management reduces stockouts, overstocking, and production delays by providing accurate visibility into raw materials and finished goods.

End-to-end supply chain integration improves coordination between procurement, logistics, and production teams, reducing lead times and enhancing material availability.

AI-driven predictive maintenance minimizes unexpected equipment failures by monitoring performance and detecting early warning signs, improving overall uptime.

Automated quality control systems ensure consistent product quality by identifying defects in real-time, reducing rework and waste.

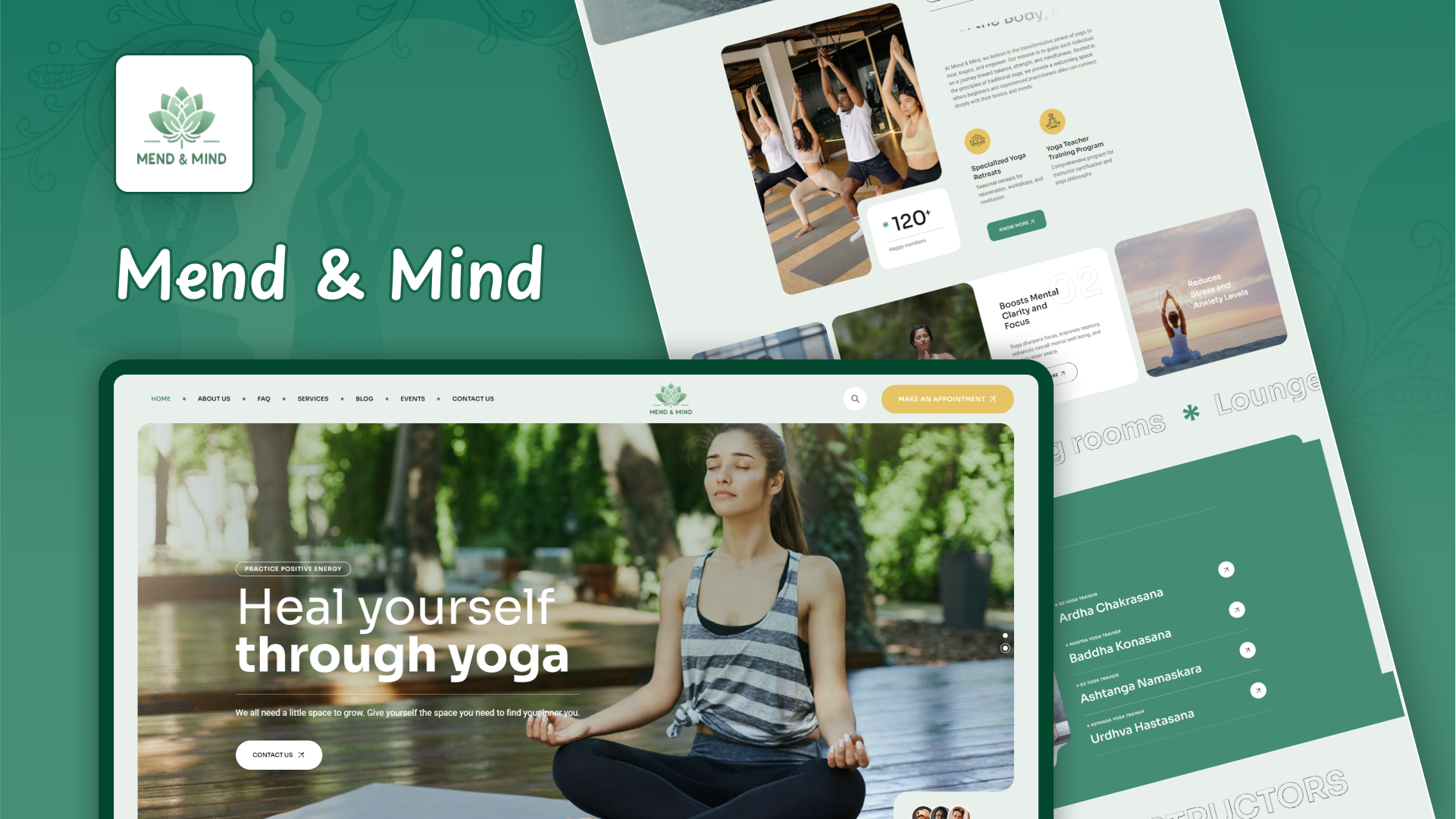

We deliver top-tier solutions at cost-effective rates, maximizing your value.

Our commitment to high standards ensures outstanding results in every project.

We keep you informed and engaged with clear, open, and timely updates.

Our services are tailored to meet your specific needs, ensuring a perfect fit.

We prioritize the safety and confidentiality of your data with robust protection.

Backed by years of experience, our skilled professionals bring deep industry knowledge to every task.

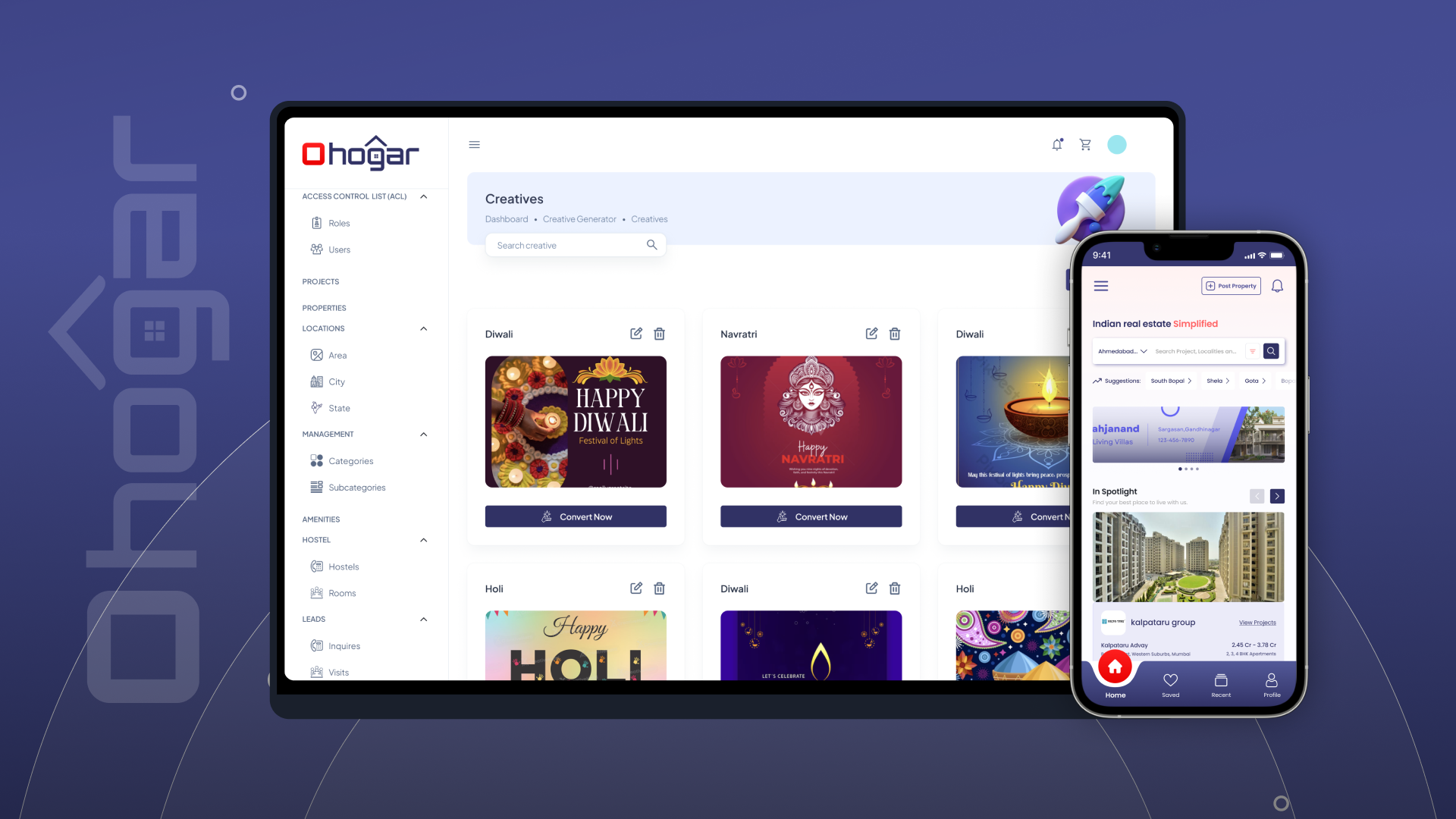

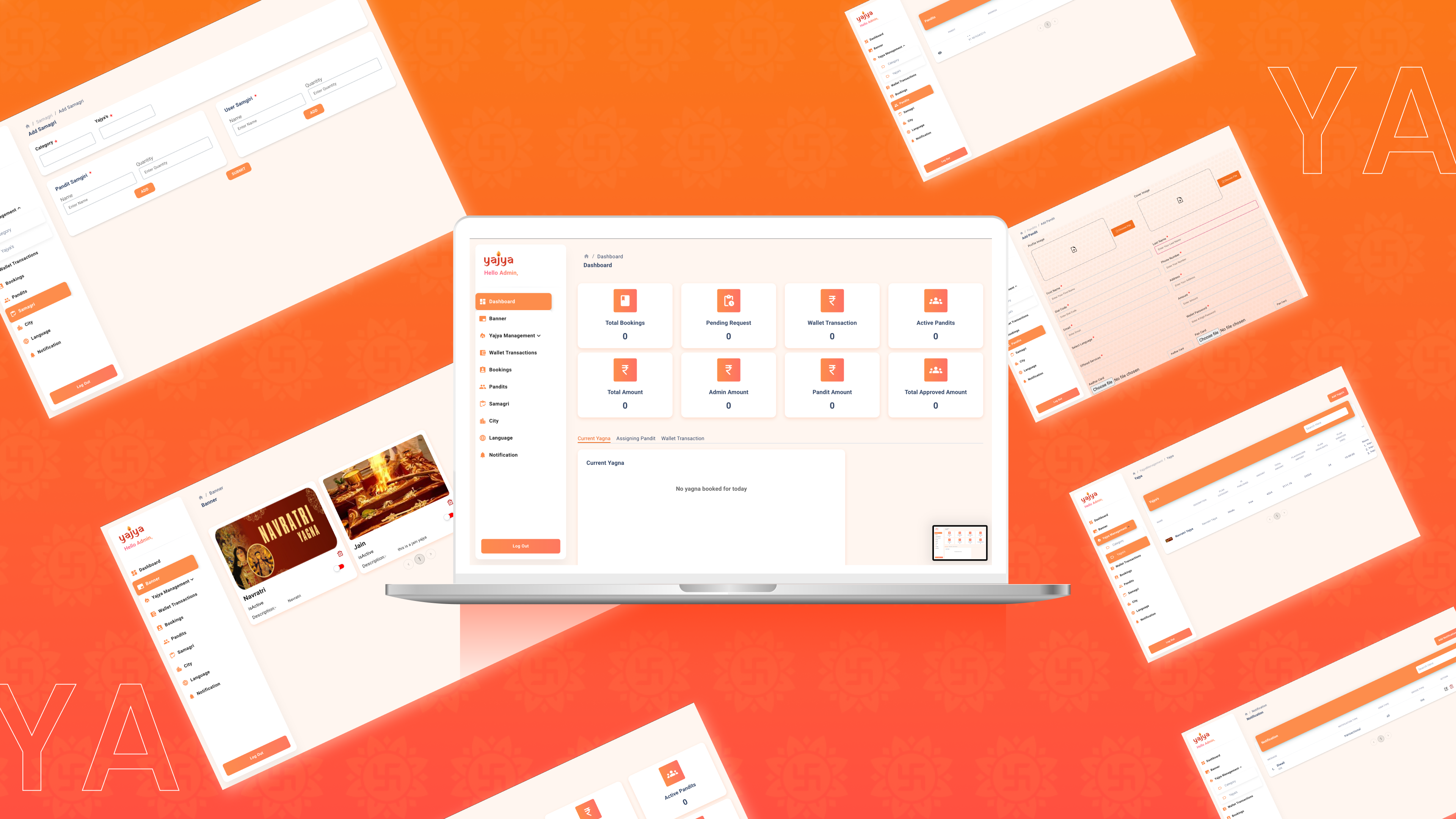

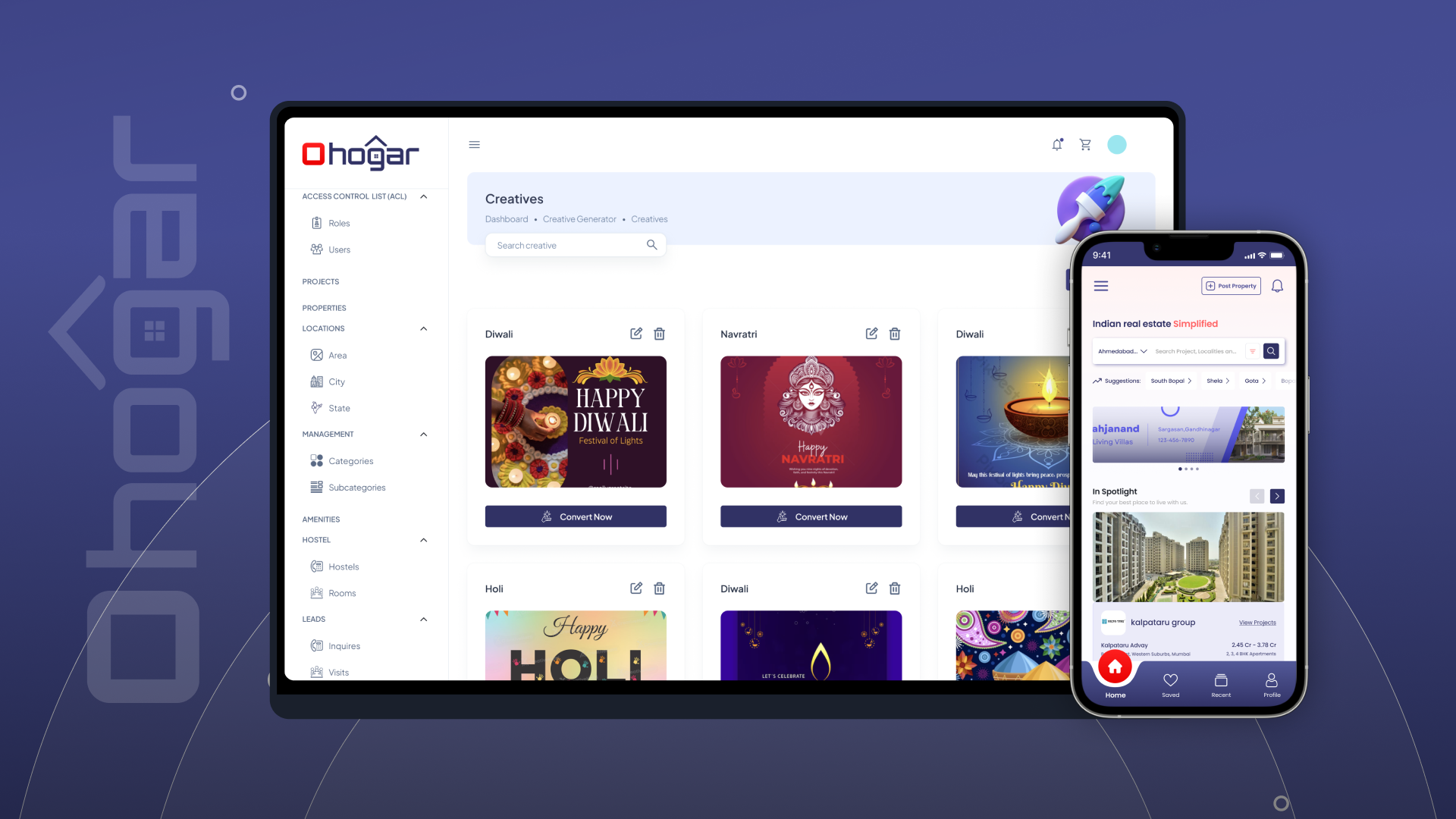

We develop solutions such as production planning platforms, inventory management systems, supply chain management, quality control automation, and manufacturing execution systems (MES).

Our platforms streamline production scheduling, automate workflows, and provide real-time monitoring, reducing downtime and optimizing resource utilization.

Predictive maintenance uses AI and IoT sensors to monitor equipment performance, detecting early warning signs of failure to prevent unplanned downtime and costly repairs.

We provide integrated supply chain solutions that improve procurement, supplier management, and logistics coordination, ensuring timely material availability and reduced lead times.

Yes, we develop automated quality control systems that detect defects in real-time, ensuring consistent product quality and reducing rework and waste.

Our platforms include real-time analytics dashboards that provide insights into production performance, equipment health, and operational KPIs, helping manufacturers make data-driven decisions.

Yes, we develop mobile-compatible platforms that allow production managers and workers to access real-time data, monitor operations, and receive alerts on the go.

Yes, our solutions can integrate seamlessly with ERP systems, centralizing data across departments for improved coordination and process automation.

Start your project with our expert IT solutions and make a lasting impact today!